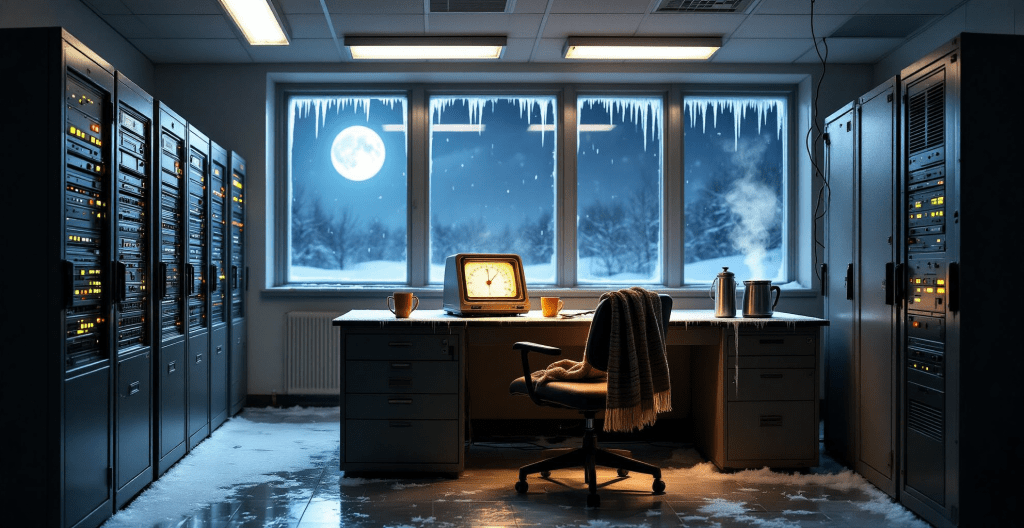

Tech historians now argue that the biggest machines performed best on a careful blend of clean chill and workplace morale. Roof louvers cracked open for a precise draft, cabinets breathed faint crystals along their seams, and raised floors exhaled a slow glitter that kept cycles calm.

Operators followed dawn rituals. Hoarfrost came off the intake grilles with a soft brush, a kettle perched on a mild radiator to keep the room just subarctic, and the crew maintained a steady hum so status lights kept their reassuring rhythm. Scarves were wrapped with geometric discipline, and everyone learned to breathe away from the tape path.

Benchmarks rose whenever the windows whitened. Tape reels turned smoother, memory felt sharper, and the machine’s voice settled into a low winter purr. Console switches clicked like icicles making decisions, and the air smelled faintly of dust, ozone, and tea that had considered boiling but chose restraint.

Evidence still lines the old rooms. Screw heads wear tiny frost halos, a coil-bound logbook shows pale rings where warm mugs once rested, and perforated tiles remember fern patterns between their holes. An anti-static brush holds a glint at its bristle tips from years of dawn duty, and a spare reel case keeps a flake that refuses to melt when the racks are listening.

When thaw arrived, technicians draped reflective blankets and offered optimistic pep talks. “You could feel throughput settle a notch the moment spring crept in,” said one archivist. “We coaxed a final week of crisp computation, then admitted the room had become a little too reasonable.” On certain evenings a single lamp still hums in the old tempo, the kettle answers with a narrow ribbon of steam, and the machine returns a result that feels pleasantly cool to the touch.

Leave a comment